Shape Memory Technology

One step ahead with ease

Since 2004, EGELHOF has been working on shape memory technology and its application in the field of building and vehicle technology. This technology offers many advantages over market-known drive technologies and is the basis of innovative new generation of electronic valves. With our team of specialists in shape memory technology, we are expanding and driving the development of this promising future technology.

Technology

The effect of shape memory alloys (SMA) is based on a thermoelastic conversion of the lattice structure, which occurs only in some alloying systems such as Ni-Ti. If a component is deformed from a shape memory alloy below a certain temperature, a reversible shape change takes place. As soon as the component is heated beyond the conversion temperature, it returns to its austenitic lattice structure and thus to its original shape. Shape memory alloys are characterized by a high power density and enable the realization of simple and noiseless drives and valves.

In addition, shape memory technology offers a wide range of innovation potentials for different products. The potentials are mainly in the areas of construction space, weight, noise emission and functional integration.

Products

Shape memory alloys in the form of wires, springs, rods or plates are developed and manufactured at EGELHOF for:

- electrically controlled drives

- thermally controlled drives

These drives are used as flap or valve drives in various applications of building and vehicle technology.

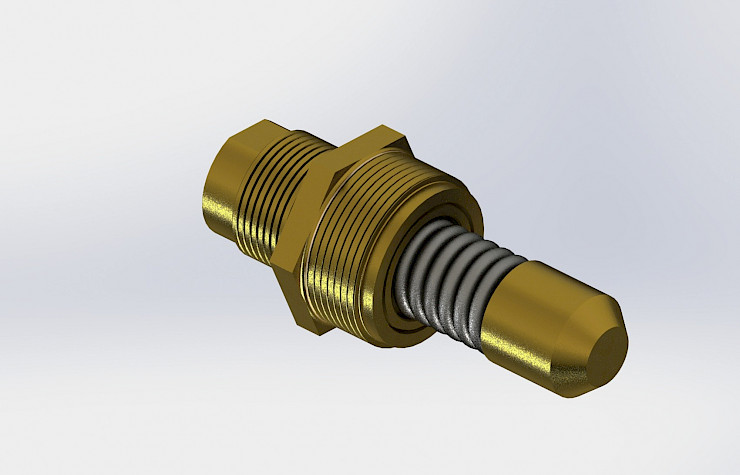

Electronic expansion valve (EXV-S)

Linear actuator (LA)

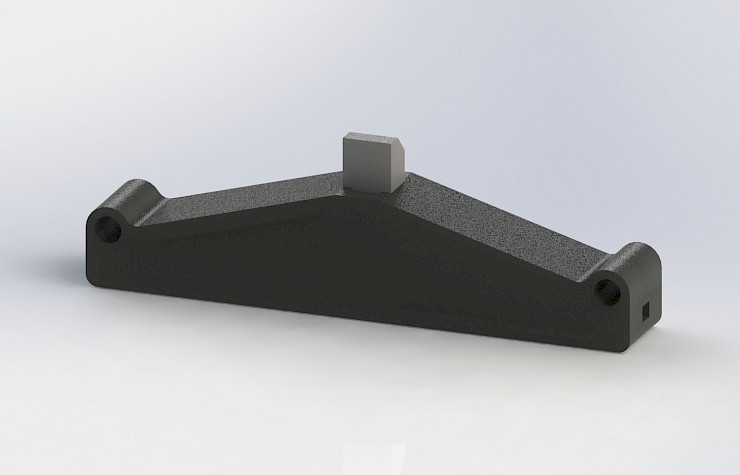

Compact actuator (FGA)

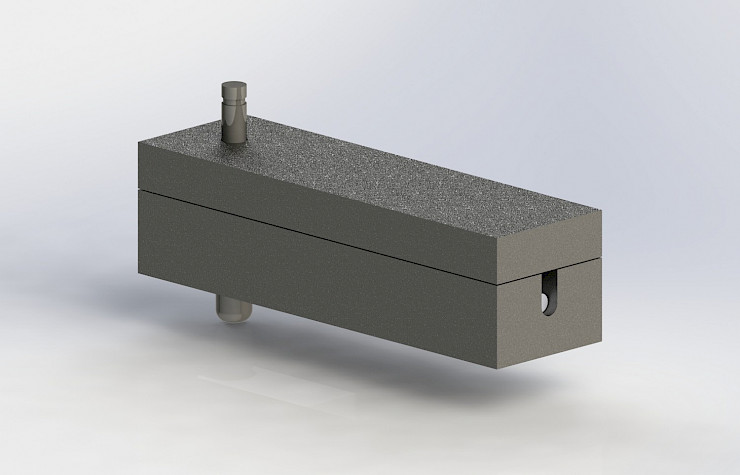

Blocking actuator (FBS)

Temperature compensation valve (RVT)

Thermostat controller (RTL)

English

English